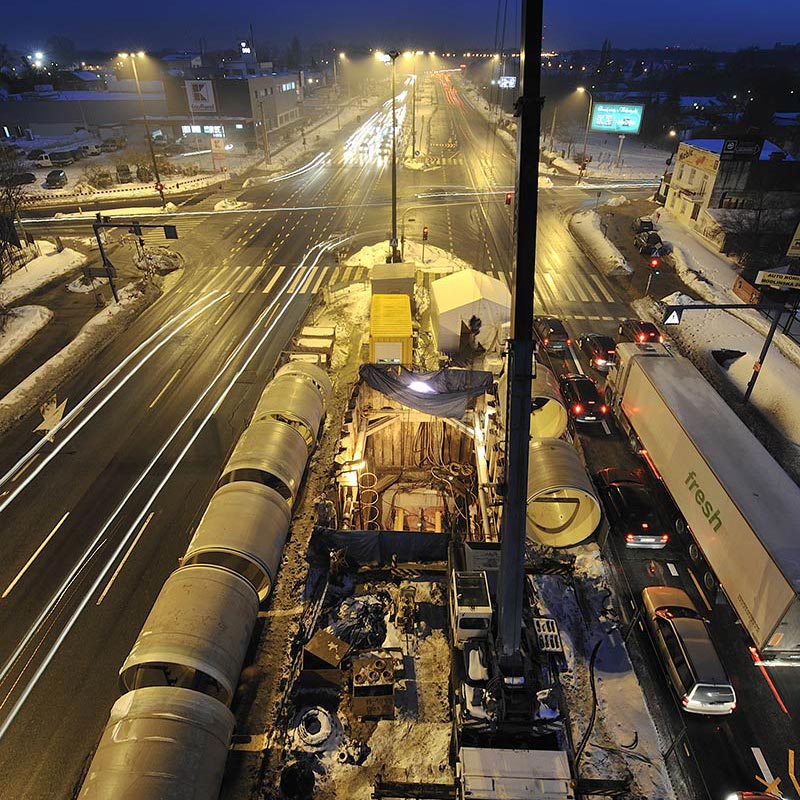

Big Savings on CO2 Emissions Thanks to Trenchless Installation

In the jacking process, pipes are pushed through the soil after a pilot drill. Since this installation method does not require opening a trench it is ideal for densely populated areas and also provides benefits for the environment: 376,734 tons of CO2 have been saved by choosing jacking over a traditional open-trench installation of a 5.7 km-long pipe section with a diameter of 3 m in Warsaw. This number equals the yearly emissions of 104,430 medium-sized cars.

Environmental Management with ISO 14001

Eco-friendly purchasing

At POLOPLAST we always aim to use packaging materials as economically as possible and choose reusable containers where viable (see photo). When buying new machines, we compare the energy efficiency and emissions of the models in question and evaluate them. Before using any raw materials, we always check that they are safe in terms of impact on our people and the environment. These consistent efforts led to all the procedures in place and to be followed being gathered together in corporate guidelines for environmentally friendly purchasing at Poloplast.

Conserving the environment with effective research and development

„XMercury“ Device in full operation 2018

The starting point for the development and finally successful implementation of the Mercury Reduction Plant “XMercury” was the Minamata Agreement launched by the UNEP in 2013, in which the cement industry was also required to make an important contribution to the reduction of global mercury emissions and inventiveness of the Wietersdorf technicians. Together with its project partners, w&p Zement GmbH saw this as an opportunity to take a pioneering role in its industry sector.

In 2013, the first preliminary tests were carried out on rotary kiln III in Wietersdorf. In 2015, the world’s first prototype plant was successfully put into operation after only six months of construction. After three years of trial operation, the “XMercury” system was put into full operation at the beginning of 2018. In the meantime, the second “XMercury” plant has already been built and put into operation in a German cement works.

With the installation of the “XMercury” plant at the Wietersdorf site, mercury emissions have been reduced by more than 80% over the past three years. Before operating the “XMercury” plant, typical monthly average levels of mercury of approximately 30-35 μg / Nm³ (ie approximately 30-40% below the currently valid limit value) were emitted. Currently, the monthly mean values are in the range of approx. 5 – 10 μg / Nm³ (ie> 90% below the currently valid limit value). The “XMercury” plant thus has a significant share in the ambitious goal of Wietersdorf cement plant of w&p Zement GmbH: to become one of the cleanest cement plants in the world.

Sustainable processes: Using alternative fuels to reduce CO2 emissions

In addition to using innovative technologies, we aim to reduce CO2 emissions by optimising existing processes in cement production. In 2016, investments were therefore made in the Anhovo plant in Slovenia to increase the proportion of alternative fuels (e.g. plastics) used in the production process. This measure led to a subsequent reduction in CO2 emissions from fossil fuels. As part of a two-year trial operation that began in late 2017, the composition of the alternative fuels used at the Wietersdorf plant has been adapted by increasing the biogenic content (e.g. fibres from the paper industry, waste timber, sewage sludge), further reducing the proportion of CO2 emissions. The next step is to use the trial operation and the associated analyses to determine the ideal fuel composition in order to sustainably reduce our company’s ecological footprint.